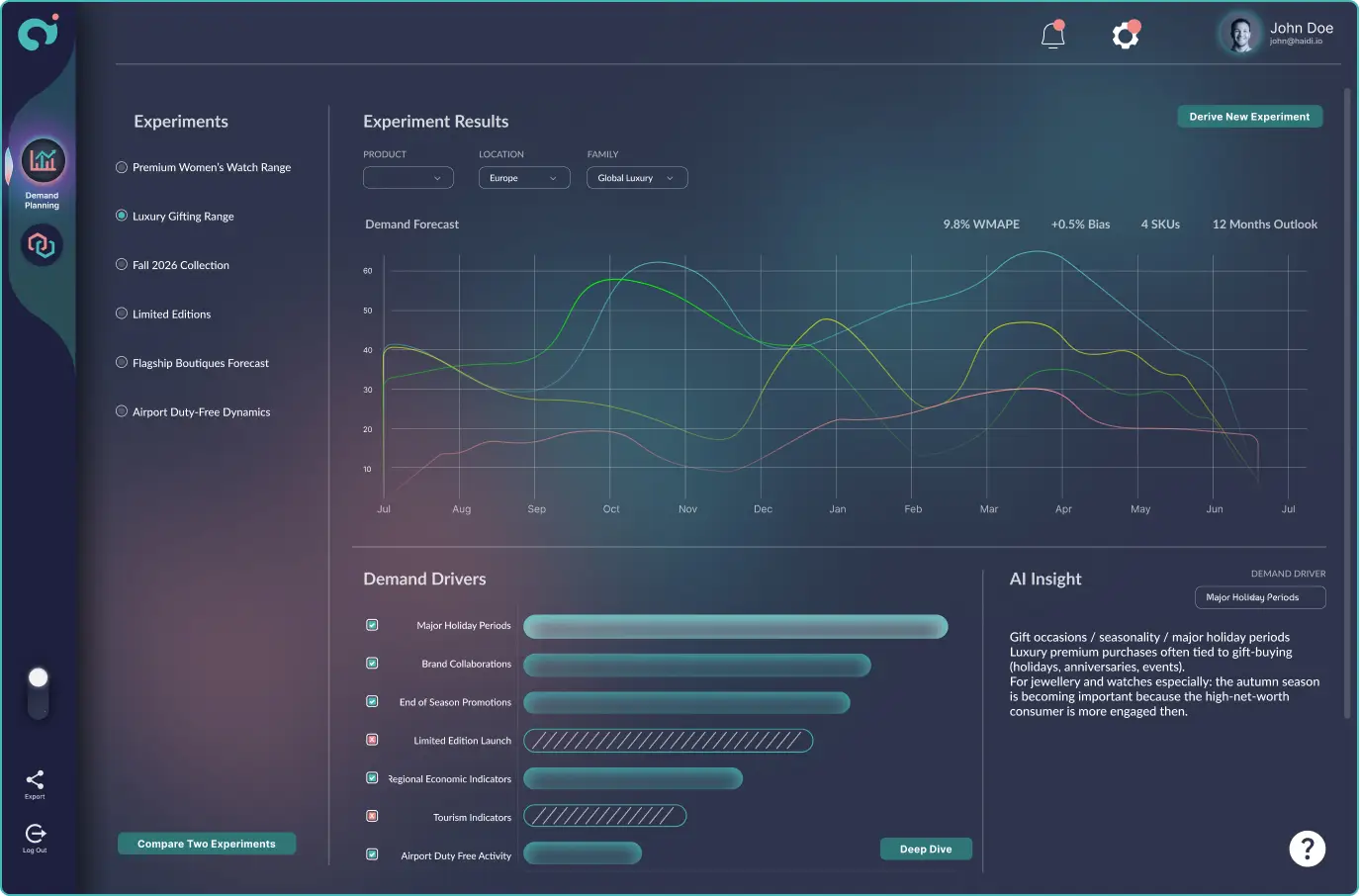

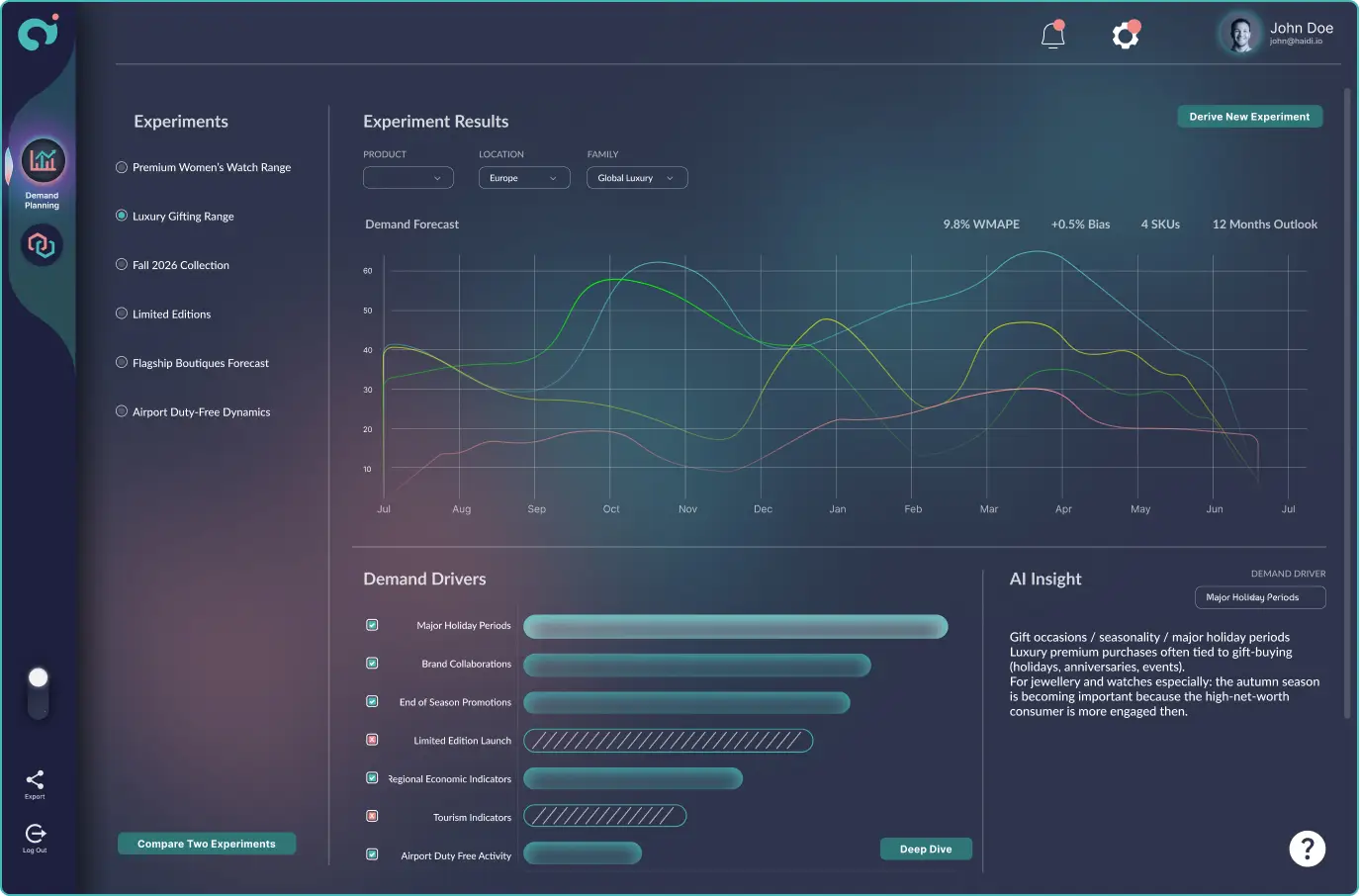

Haidi helps you understand the impact of different demand drivers – such as price, promotions, external events etc., and measure how much each one influences sales. Once the analysis is done, Haidi automatically translates those insights into the logic powering your demand-planning model.

Everyone has their own spreadsheet, no one agrees on the numbers, and by the time decisions are made, it’s already too late.

Different teams work off different spreadsheets, no one agrees on the numbers.

Underproduction leads to shelves sitting empty when customers need products.

Poor planning causes excess production and unnecessary waste.

Messy data slows down decisions – by the time you react, it’s too late.

Bad demand planning means products aren’t available when customers are ready to buy.

Too much stock is produced just to “be safe,” tying up cash and space.

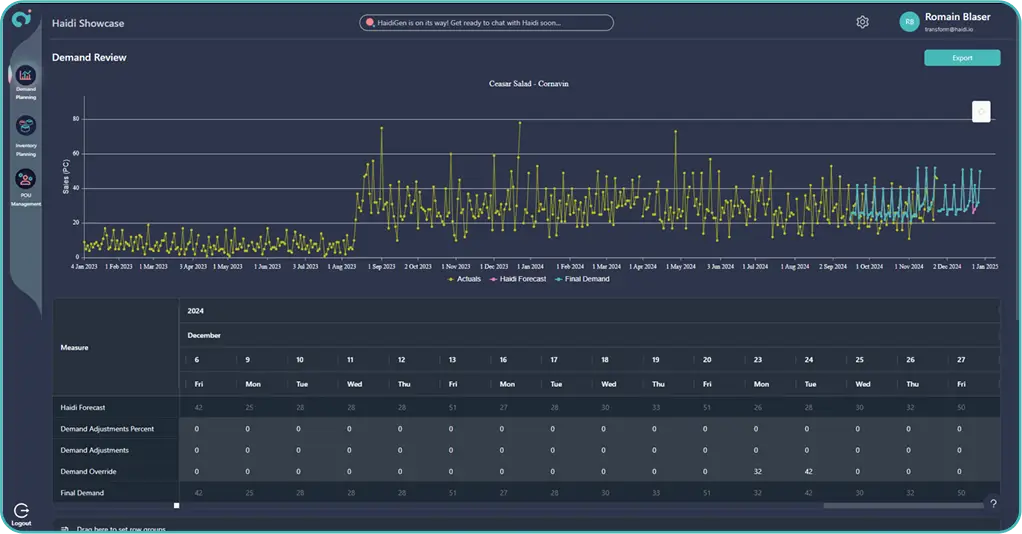

We have developed an easier path to fewer stockouts, less waste, and on-time orders called Noise in – Decision Out, you just have to provide us your raw data, and we do all the dirty work and give you the best possible plan that you can review and challenge

Share you raw data

We will ingest it and clean it, if something’s missing we’ll flag it for your review

We run your data through Haidi

Haidi uses AI to merge your data and compute a tailored forecast and inventory plan

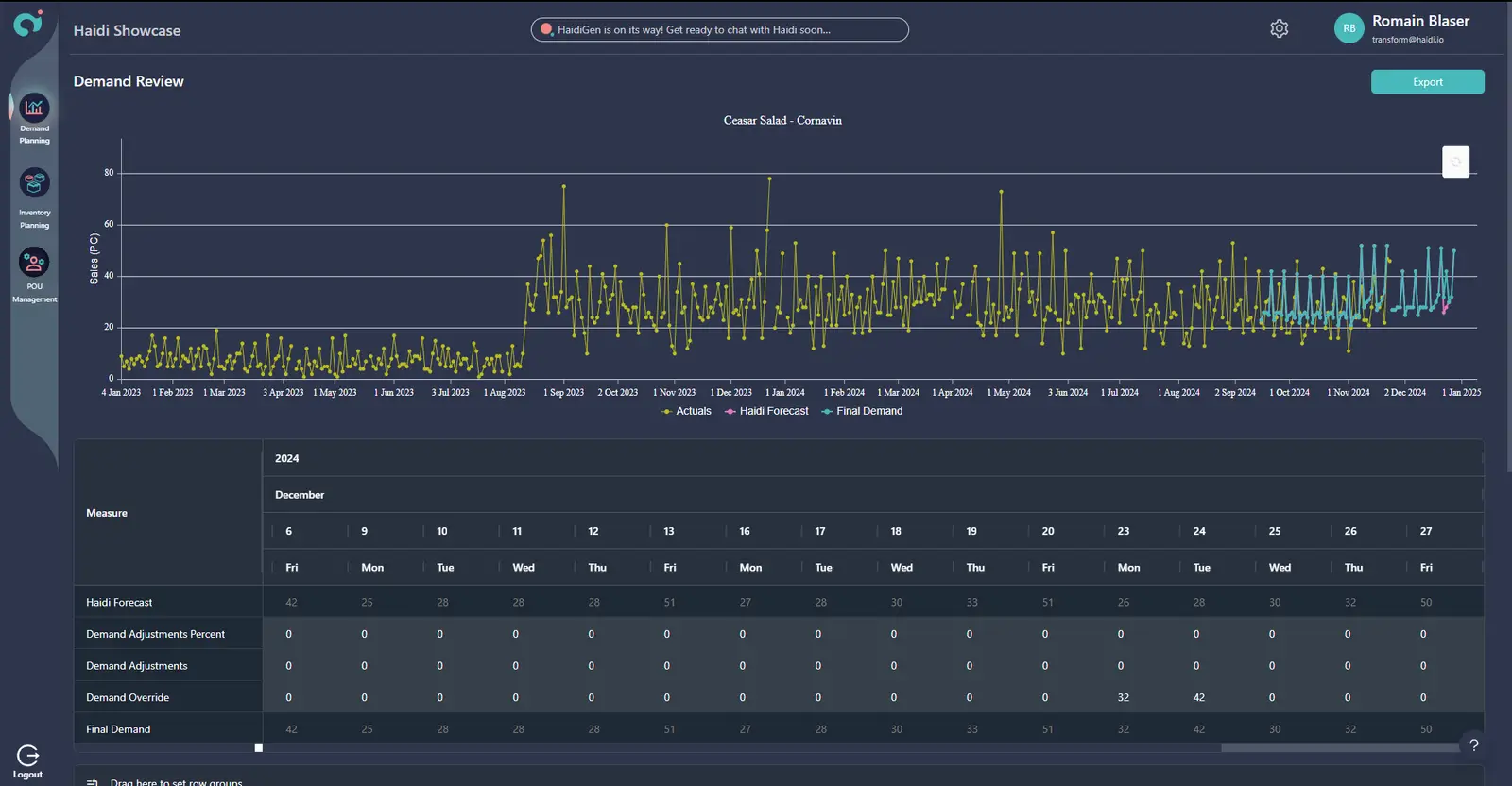

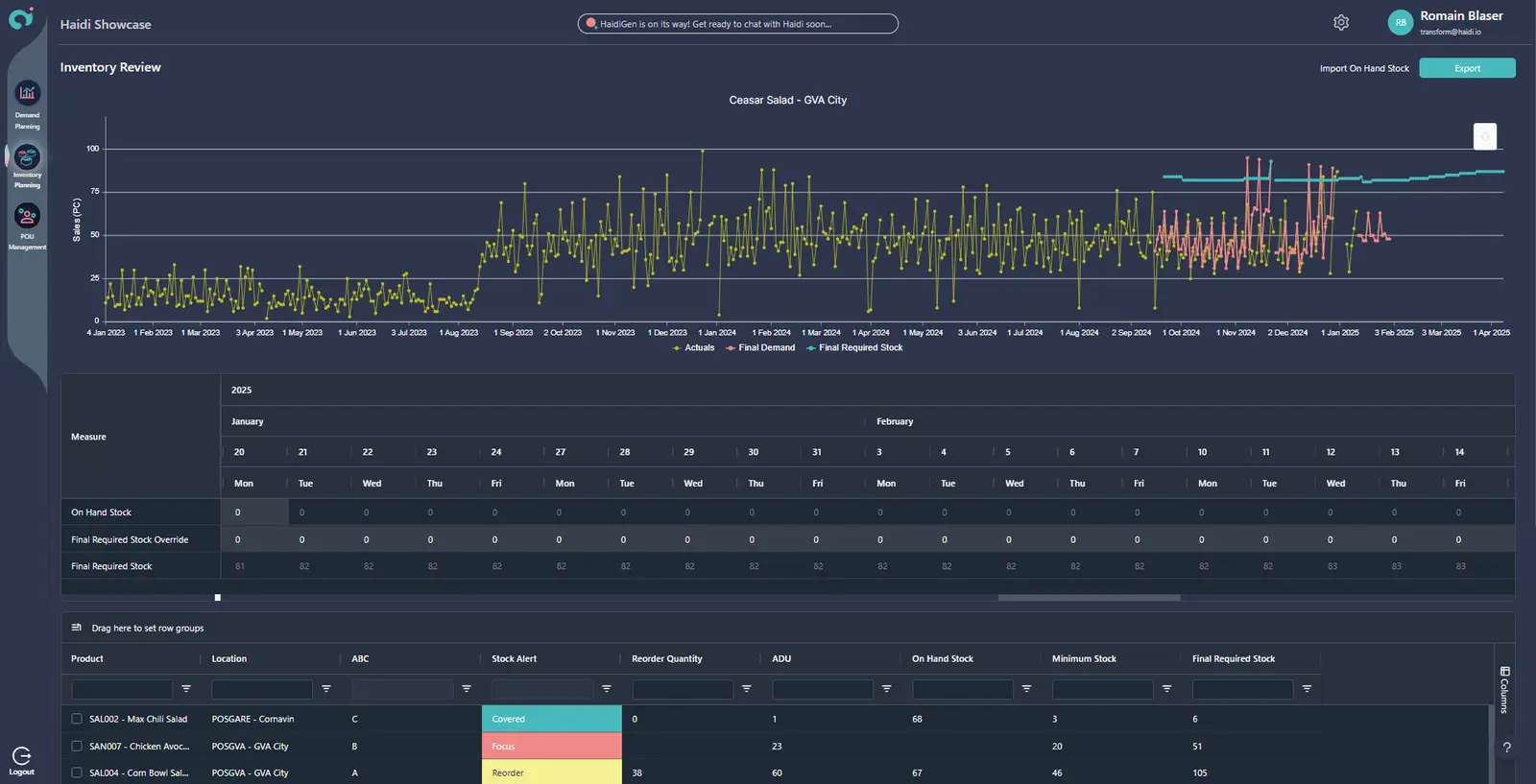

Review the results

You review the plan, challenge the insights, and make it available for execution – clear, simple, and ready to go.

Retailers and FMCG brands face constant swings in demand. Promotions, seasonality, and consumer habits change fast, making it hard to balance shelves between too much stock and empty aisles.

Products going to waste because forecasts overshoot demand.

Empty shelves during key promotions, losing sales and customer trust.

Warehouses full of unsold goods while other items run out.

Suppliers struggling to keep up with sudden demand shifts.

Pharma companies operate under strict regulations where shelf life and product availability are non-negotiable. A small error in planning can either stop patients from getting medicine or lead to millions lost in expired drugs.

Medicines expiring in warehouses due to poor visibility of shelf life.

Underproduction of critical drugs, leaving clients waiting.

Bottlenecks when raw materials (APIs) or packaging are delayed.

Overstocking expensive inventory that ties up capital and risks write-offs.

With perishable products, every wrong planning decision shows up as waste on the floor. Seasonal peaks, short shelf lives, and supplier delays make balancing freshness and availability one of the toughest challenges.

Fresh products expiring before they ever reach consumers.

Seasonal spikes (like holidays) leading to under- or over-production.

Packaging or raw material shortages stopping production lines.

Supermarkets facing empty fridges on high-demand days.

Grid operators and contractors rely on standard specs and steady access to the right parts to keep projects on track and maintenance work running without delays.

Project delays when transformers, cables etc. have long lead times.

Wrong spares at depots so crews cannot fix outages on the first visit.

Fragmented specs cause old parts to pile up while new ones run short.

Supplier bottlenecks that push costs up and push dates out.

Haidi helps you understand the impact of different demand drivers – such as price, promotions, external events etc. – and measure how much each one influences sales. Once the analysis is done, Haidi automatically translates those insights into the logic powering your demand-planning model.

Control the factors that shape your demand.

Measure how each driver affects performance and trends.

Simulate scenarios across short, mid, and long-term horizons.

Haidi connects your internal data with external factors – like weather, market trends, or local events – to build forecasts that reflect reality.

Haidi helps you build smart inventory plans by understanding real demand signals and guiding you to stock exactly what’s needed.

Fill out the form and we’ll get back to you as soon as we can

A clean forecast, inventory plan, and clear next steps – tailored to your business.

Your sales history, stock levels, and basic product info. That’s it – we’ll guide you through the rest.

In as little as 2 days after you upload your data. No long project. No waiting.

Nope. Just your data. Haidi handles the rest, the platform is meant to be easy.

Yes. We support both manual uploads and automated ERP connectors (SAP, Odoo, MS Nav, etc.).

We flag what’s missing, show the impact, and help you decide what to do. You stay in control.

– Merges internal + external signals (market trends, weather, events)

– Runs smart algorithms to forecast and size inventory

– Gives concrete recommendations, not just charts

When we spoke on the radio about India’s future, we shared a simple vision: India doesn’t just need global technology – it needs technology built in India, for India. Haidi is part of that journey – a platform born in Switzerland, now growing roots in India, empowering local industries to plan, forecast, and decide with confidence.

In this extract from the Le Temps webinar on India, Haidi highlights the principles that guide our work: trust built first, relationships developed over time, presence that’s consistent, and pricing grounded in reality. These fundamentals shape how Haidi grows and supports industries in India.