Add Your Heading Text Here

Demand Planning Excel Dashboard: Why Advanced Planning Systems Outperform Excel in Demand & Inventory Planning

Pablo Raubert | March 12 th 2025

In today’s highly dynamic supply chain environment, demand & inventory planning are no longer just operational functions, they are strategic musts. Yet, many companies continue to rely on demand planning excel dashboards, tools that are never designed to handle the scale, complexity, and speed required for modern planning.

While spreadsheets may seem familiar, they lack the automation, intelligence, and scalability needed for effective decision-making. This results in inefficiencies, inaccuracies, and missed opportunities that can erode competitiveness and profitability.

Advanced Planning Systems (APS) like Haidi offer a smarter, faster, and more reliable alternative. By integrating real-time data, AI-driven forecasting, and automated workflows, APS solutions empower businesses to move from reactive to proactive planning, optimizing both demand forecasting and inventory levels.

Why APS Outperforms Demand Planning Excel Dashboards in Demand & Inventory Forecasting

1. Synchronized Planning: Breaking Silos, Driving Alignment

Demand Planning Excel Dashboards are fragmented and static, making it difficult to align teams, maintain accuracy, and respond to changes in real time. APS solutions create a single source of truth, consolidating demand and inventory data into one real-time platform, eliminating:

- Data silos

- Version control issues

- Cross-functional misalignment

Beyond data integration, APS platforms synchronize demand planning with procurement, production, and finance, ensuring forecasts directly translate into actionable supply plans. With real-time collaboration, organizations can plan concurrently, accelerating decision-making and increasing agility.

2. High-Value Decision-Making: From Manual Work to Strategic Focus

Managing thousands of SKUs in Excel is manual, slow, and error-prone. APS solutions automate repetitive tasks and exception-based planning, allowing planners to focus on strategy instead of data entry.

Moreover, APS enables real-time scenario modeling and what-if analysis—empowering businesses to:

- Simulate disruptions

- Assess demand shifts

- Adjust plans dynamically

In contrast, Excel makes such analysis cumbersome, limiting visibility and slowing response times—a risk companies can no longer afford.

3. AI-Driven Forecasting: Smarter, More Accurate, Less Effort

While Excel can run statistical models, maintaining and scaling these across an entire product portfolio is inefficient. APS platforms leverage AI-powered forecasting, continuously improving accuracy by detecting emerging trends, seasonality, and demand fluctuations in real time.

With embedded machine learning algorithms, APS solutions self-adjust forecasts, minimizing human intervention while optimizing inventory levels to avoid both stockouts and excess stock.

- Higher forecast accuracy

- Less manual intervention

- Better responsiveness to market fluctuations

The result? A resilient supply chain that adapts to real-world demand changes.

4. Intelligent Analytics: From Raw Data to Actionable Insights

Excel struggles to provide real-time, interactive insights needed for agile decision-making. APS solutions enable:

- Multi-dimensional data exploration – Slice and dice data dynamically by product, region, or time horizon

- Built-in analytics & AI-powered insights – Identifies demand patterns and inventory optimization opportunities

- Interactive dashboards – Transforms data into a powerful decision-making engine

Instead of relying on static spreadsheets, APS provides a real-time, predictive view of demand and inventory—empowering businesses to act, not react.

Real-World Example: The Cost of Excel’s Limitations

A company planning its Yearly Forecast Supplier Commitment in Excel encountered an update malfunction that inadvertently increased the commitment by 35%. The result?

- Excess inventory that required costly storage and movement

- Increased risk of obsolescence and write-offs

- Financial losses and inefficiencies

This example underscores the vulnerabilities of relying on Excel for mission-critical planning and highlights the need for a more robust, automated solution like APS.

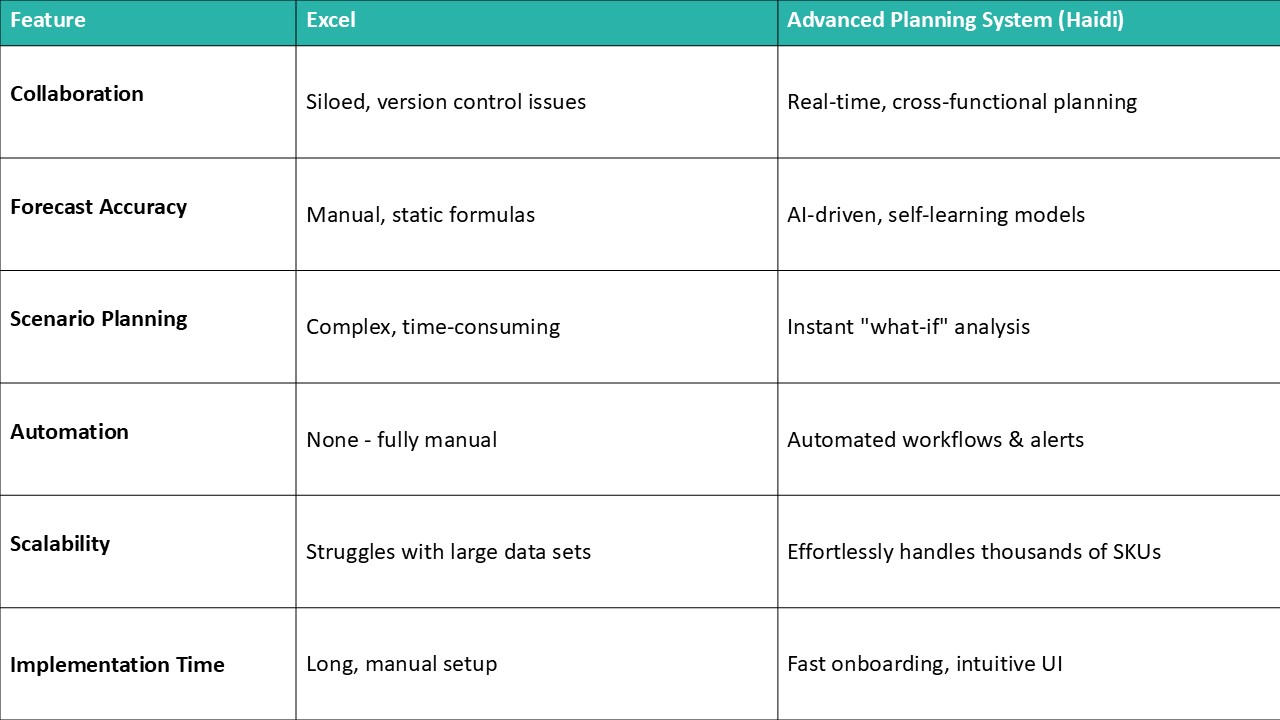

Comparison: Excel vs. Haidi APS

The Future of Demand Forecasting and Inventory Planning

The complexity of modern supply chains has outgrown Excel. Businesses that fail to modernize their forecasting and inventory planning risk inefficiencies, misalignment, and financial loss, ultimately falling behind in an increasingly competitive landscape.

APS solutions like Haidi provide the speed, intelligence, and integration needed to navigate uncertainty and drive supply chain resilience.

- Faster, more accurate decision-making

- Optimized demand forecasting and inventory levels

- Seamless collaboration across business functions

The choice is clear: continue relying on outdated spreadsheets or embrace an AI-powered APS that delivers agility, accuracy, and efficiency.

The future of demand forecasting and inventory planning is already here—businesses must act now to stay ahead.

Contact us